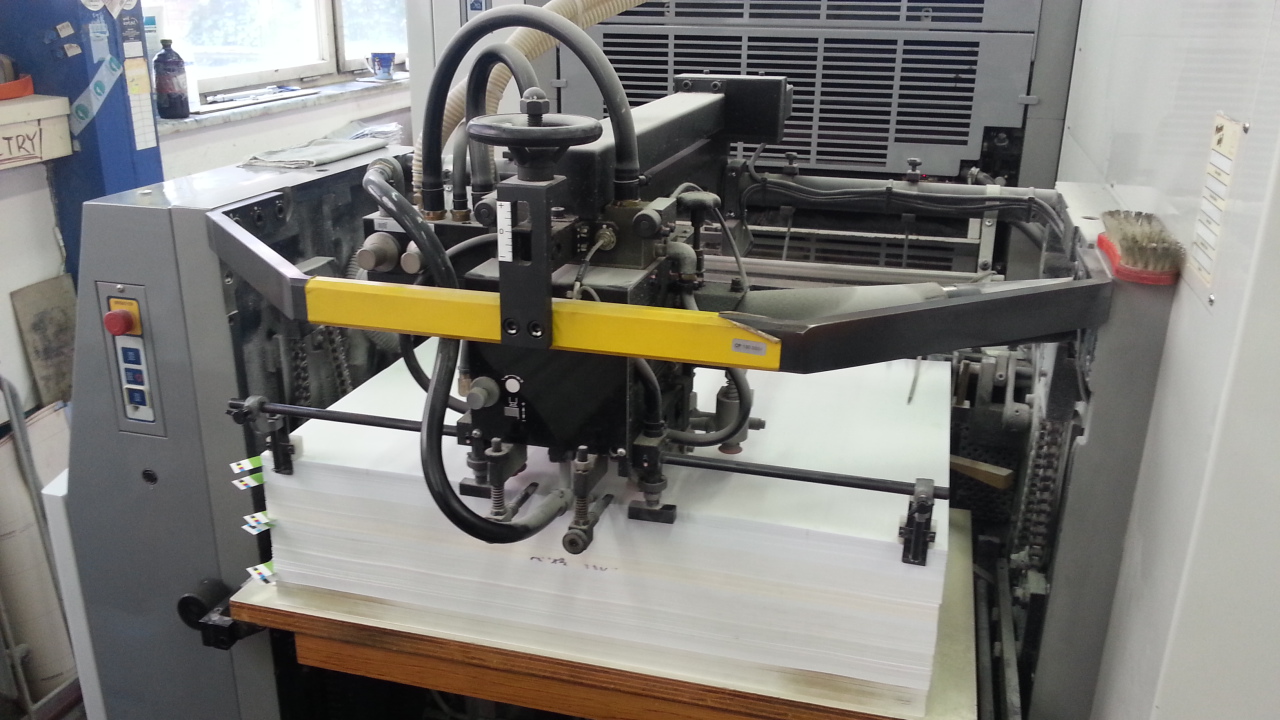

Popis

gsm : from 40 to 400 g / m2

SAS (sheet size and thickness preset device),

Suction belt feeding,

Anti static eliminator bars,

Front guide sensor,

Side lay sensor,

Ultra-sonic double sheet detector,

Mechanical double sheet detector,

Automatic ink roller wash-up,

Ink duct time adjustment systém,

Continuous dampening systém,

SPC automatic plate changing,

Remote control plate cylinder adjustment,

Automatic running register.

Automatic cocking,

Automatic impression adjustment systém,

Automatic perfecting changeover,

Quick release blanket bar,

Semi-high pile,

Motorized positioning delivery vacuum wheels,

Motorized delivery pile board,

Powder spray device,

Sheet curling prevention device,

Dtc i -delivery top console type i (or scc i -sakurai color console type i) SIS-sakurai interactive systém,

Blanket wash up device(baldwin-super washer)

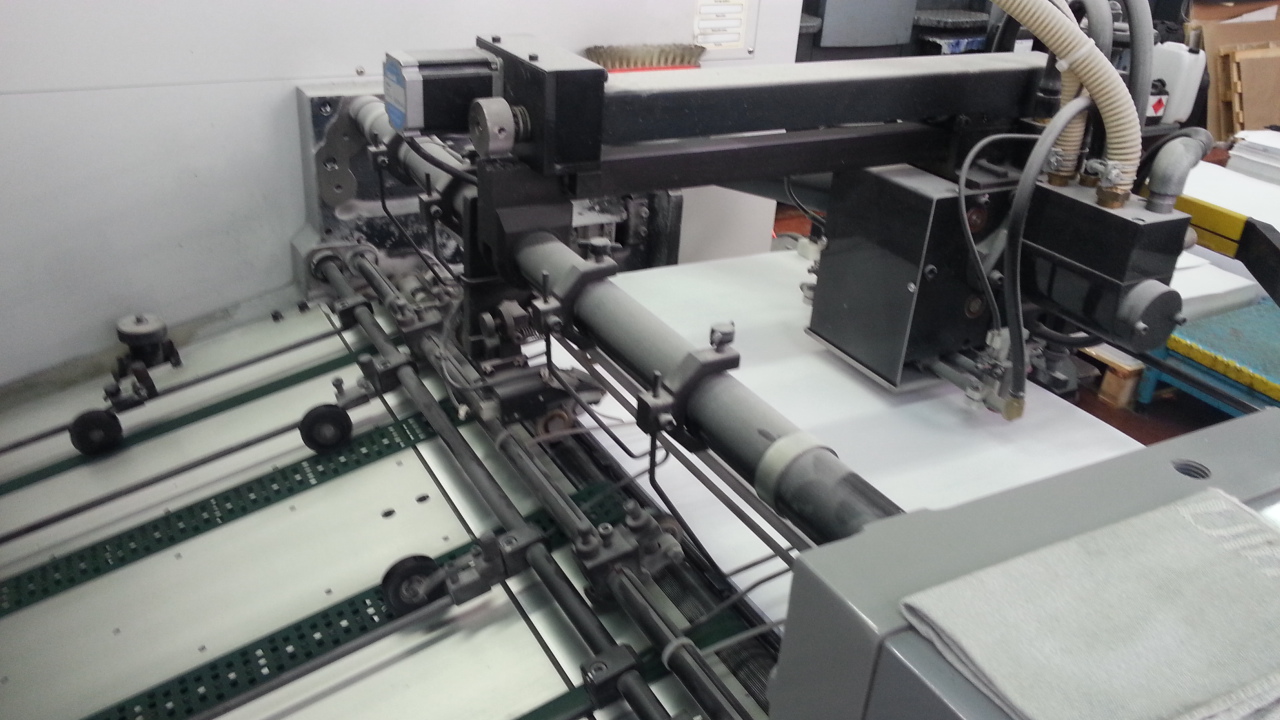

equipment:

Qss-quick stand-by system (scc iii or dtc iii)

Synchronous wash-up system (blanket and ink roller wash-up)

Cip3/4 interface

Oscillating ink form roller

MTD Techkon

Suction belt feeding,

Anti static eliminator bars,

Front guide sensor,

Side lay sensor,

Ultra-sonic double sheet detector,

Mechanical double sheet detector,

Automatic ink roller wash-up,

Ink duct time adjustment systém,

Continuous dampening systém,

SPC automatic plate changing,

Remote control plate cylinder adjustment,

Automatic running register.

Automatic cocking,

Automatic impression adjustment systém,

Automatic perfecting changeover,

Quick release blanket bar,

Semi-high pile,

Motorized positioning delivery vacuum wheels,

Motorized delivery pile board,

Powder spray device,

Sheet curling prevention device,

Dtc i -delivery top console type i (or scc i -sakurai color console type i) SIS-sakurai interactive systém,

Blanket wash up device(baldwin-super washer)

equipment:

Qss-quick stand-by system (scc iii or dtc iii)

Synchronous wash-up system (blanket and ink roller wash-up)

Cip3/4 interface

Oscillating ink form roller

MTD Techkon